Die Herstellung von Seife auf kaltem Wege (also ohne Erwärmen oder Kochen des Seifenleims) ist – im Vergleich zur mehreren Tausend Jahre alten Geschichte der Seife relativ jung. Möglich wurde sie erst vor ca. 200 Jahren durch

- die Verfügbarkeit leicht verseifbarer Öle und Fette (Kokosöl, Palmfett).

- die Verfügbarkeit von reinem Natriumhydroxid (NaOH)

- die Verfügbarkeit mechanischer Rührwerke.

Einer der Erfinder des

Originaltext des Patents von 1839

Specification of a Patent granted to WILLIAM HAWES, of Old Barge House, Christchurch, in the County of Surrey, Soap Manufacturer, for Improvements in the Manufacture of Soap, parts of which Improvements are also applicable to Preparing Tallow for the Manufacture of Candles. — Sealed December 12, 1839.

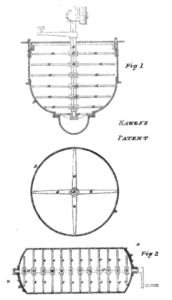

WITH AN ENGRAVING.

To all to whom these presents shall come, &c., &c. — Now know ye, that in compliance with the said proviso, I, the said William Hawes, do hereby declare that the nature of my said invention, and the manner in which the same is performed, are fully described and ascertained in and by the following statement thereof; reference being had to the drawings hereunto annexed, and to the figures and letters marked thereon (that is to say) : —

In making soap according to the modes now in use, combining of tallow or other fatty matters with the alkali is effected in a copper by boiling, and saponification goes on during such boiling process. Now my invention re- relates to a mode of making soap by intimately com bining and mixing the ingredients of soap by mechanical means without boiling, thus producing a saponification of the tallow or other fatty matters employed at a low tem perature, and without submitting the materials for soap- making to that high degree of heat, which heretofore has been the means of mixing and bringing the particles of tallow, and the alkaline ley, into intimate contact to effect their combination or saponification ; by which means I am enabled to obtain a more beneficial result, and at a less expenditure of fuel ; and in order to give the best infor mation in my power, I will proceed to describe the pro cess pursued by me, and which I have found fully to answer.

Description of the Process.

I take any given quantity of tallow, say two and a half tons, and having melted it, keeping the temperature as low as possible, I mix it with the quantity of alkaline ley, which is required completely to saturate the tallow, to convert into soap ; and such mixing I perform by me chanical means, and the apparatus or machinery I employ is hereafter described. I use the ordinary ley of soap boilers, preferring that made from the strongest and purest alkali. The saponification of the tallow or other fatty mat ter, may be ascertained by the absorption of or combination of the tallow, oil, or other fatty matter, with the ley, care having been taken in the first instance to use sufficient quantity thereof, or about twenty gallons of ley made from the strong alkali, above referred to, and of the speci fic gravity of 1.125 water, being unity, or a smaller quan tity if the specific gravity is higher, (that being determined by the quantity of free or caustic alkali in the ley) to every one hundred pounds of tallow. It is necessary to state that various descriptions of fatty matters, require different proportions of alkali to convert them into soap, and that provided there is sufficient, the quantity is immaterial, and the method of ascertaining the quantity of alkali in the ley, being that now generally in use and well known to soap manufacturers. This combination of the tallow or other fatty matters, and the ley may be made in one of the ordinary coppers now in use by soap makers, with the addition of a machine to produce their intimate ad mixture, and the minute division of the tallow.

Should a cylinder be employed, then immediately upon its being charged with either the ley or the tallow (the tallow at a temperature just sufficient to keep it fluid,) the tallow or ley, as the case may be, may be pumped or run in, and motion given to the shaft and stirring ap paratus, which being continued in a vessel of the size described from three to four hours, or less time if the mass becomes thick sooner, will ensure the perfect mix ture of the materials, and prepare the tallow for saponi- fication which is evinced by the evolution of heat. As the benefit of this process arises mainly from the saponi- fication of the ordinary materials in a comparatively cold state, it is desirable, as soon as the mass thickens and the ley is absorbed, that the cylinder should be emptied and the contents turned into an ordinary copper,^preparatory to their being finished and converted into yellow soap, by the addition of resin, or into mottled or white soap, by the operations of finishing leys as at present practised, and as is well known to every soap manufacturer. By this transfer from the cylinder to the ordinary copper, time is allowed for the combination of the tallow and alkali to become, chemically speaking, perfect. In the description of the process above given, I have generally spoken only of tallow, in order to prevent repetition of words, but it should be understood that the same description applies to oils, some of which will not require melting or warming, and other fatty matters usually employed in soap making.

I would remark, that although I have given the description of the machine I employ for mechanically mixing of the tallow and alkaline ley, I do not confine myself thereto, as variations may be made therein, or other mechanical means may be resorted to, so long as an intimate mixing of the matters be effected, in order to the bringing of the particles of the tallow in intimate contact with the alkali, that saponifi- cation may take place without the application of boiling heat.

Having thus explained the nature of my invention, so far as it relates to the manufacture of soap, I would candles. In saponifying tallow and other fatty maters as a prepa ratory process applicable to the making of candles, that process has been heretofore performed by boiling the fatty matters with lime in the state known as cream of lime, and the saponification and mixing has been performed by boiling. Now this part of my invention consists in mechanically mixing the alkali or lime employed with the tallow, without boiling, in the same manner as that above described, and thus producing a saponification of the tallow or fatty matter, which when so obtained is to be subsequently treated in like manner to like matters when mixed and saponified when using heat.

Having thus described the nature of my invention, I would have it understood that what I claim as my inven tion is, first, the mode of combining mechanically tallow, oils, or other fatty matters, and alkali for producing saponification in soap making, avoiding submitting the matters to that high degree of heat heretofore resorted to, in mixing the ingredients for saponifying tallow, or other fatty matters, in soap making, as above described ; and, Secondly, I claim, the mode of saponifying tallow, and other fatty matters (in preparing the same for making candles) by mechanically mixing the same with the alkali employed, as above described. — In witness where of, &c.

Enrolled December 12, 1839.